MWG medium wall adhesive lined shrinkable tubing, non-flame retardant

Medium wall shrinkable tubing is manufactured by extrusion method from radiation-crosslinked polyolefin, non-flame retardant.

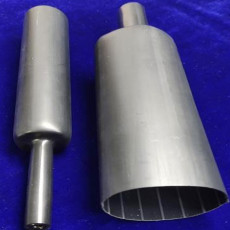

Brief description: Medium wall shrinkable tubing is manufactured by extrusion method from radiation-crosslinked polyolefin, non-flame retardant. Hot-melt adhesive based on ethylene-vinyl acetate copolymer is applied to the inner side.

Application: Multipurpose medium wall adhesive lined shrinkable tubing is used for electrical insulation, sealing and mechanical protection of wires, wires splices, cable fittings, metal products subject to corrosion, etc. During thermal shrinkage of the tube adhesive is melting and distributed over the surface of the product, filling the voids, and after hardening it provides sealing and additional mechanical strength. Tube can be used in the production of termination and joint heat-shrinkable kits.

Package: Tube is supplied in pieces of 1,22m and 1m. Can be packed in carton boxes and packaging film / bags.

Storage: in clean, dry rooms in the supplier's packaging or in cardboard boxes, at a relative humidity of up to 70%, at temperatures from -10 ° C to +50 ° C, avoiding sudden temperature changes and exposure to direct sunlight. The distance to any heating sources should be at least 1 meter (without exceeding the maximum storage temperature). Storage conditions should exclude the influence of aggressive medium: acids, alkalis, fuels and lubricants, solvents, etc. Tubes with adhesive layer require storage in tight bags/boxes to avoid contamination of the adhesive layer of the tubes with dust and dirt inclusions of various origins, which can negatively affect the adhesion.

The shelf life is at least 2 years from the date of shipment subject to storage conditions.

Certification: Not subject to mandatory certification.

Basic technical specifications:

|

Operating temperature |

from -40°С to +125°С (without adhesive layer) * |

|

Shrink temperature |

+125°С |

|

Shrink Ratio |

from 3 : 1 to 4 : 1 |

|

Flammability |

Non-flame retardant |

|

Base color |

Black |

|

Size range: |

Inner diameter from 8,0 to 260mm |

|

Longitudinal shrinkage: |

≤ 10% |

*- recommended to limit the maximum operating temperature to +90 ° C, in order to avoid melting and leakage of adhesive.

Additional Technical details:

|

Parameter |

Test Method |

Result |

|

Tensile strength, МPа |

ASTM D2671 |

Not less than 12 |

|

Breakdown elongation |

ASTM D2671 |

≥ 400% |

|

Tensile strength after heat aged, МPа |

UL224 (+158°C х 168h) |

Not less than 10 |

|

Relative elongation after heat aged, % |

UL224 (+158°C х 168h) |

≥ 300% |

|

Dielectric strenth, kV/mm |

IEC 60243 |

≥ 20 |

|

Volume resistivity, Ω·cm |

IEC 60093 |

≥ 2,5 х 1014 |

|

Water absorbtion, % |

ASTM D570 |

Less than 0,2 |

|

Adhesive: melt point, °C |

ASTM E28 |

95 ± 5 |

|

Size, mm |

ID before shrink, mm |

ID after full shrink |

Wall thickness after shrink, mm |

|

Ø 8 / 2 |

≥ 8,0 |

≤ 2,0 |

1,85 ± 0,30 |

|

Ø 9 / 3 |

≥ 9,0 |

≤ 3,0 |

1,85 ± 0,30 |

|

Ø 12 / 4 |

≥ 12,0 |

≤ 4,0 |

1,85 ± 0,30 |

|

Ø 16 / 5 |

≥ 16,0 |

≤ 5,0 |

2,15 ± 0,35 |

|

Ø 19 / 6 |

≥ 19,0 |

≤ 6,0 |

2,40 ± 0,40 |

|

Ø 25 / 8 |

≥ 25,0 |

≤ 8,0 |

2,70 ± 0,40 |

|

Ø 28 / 9 |

≥ 28,0 |

≤ 9,0 |

2,70 ± 0,45 |

|

Ø 33 / 8 |

≥ 33,0 |

≤ 8,0 |

3,30 ± 0,45 |

|

Ø 35 / 9 |

≥ 35,0 |

≤ 9,0 |

3,30 ± 0,45 |

|

Ø 40 / 12 |

≥ 40,0 |

≤ 12,0 |

3,30 ± 0,45 |

|

Ø 43 / 13 |

≥ 43,0 |

≤ 13,0 |

3,30 ± 0,45 |

|

Ø 55 / 16 |

≥ 55,0 |

≤ 16,0 |

3,30 ± 0,45 |

|

Ø 65 / 19 |

≥ 65,0 |

≤ 19,0 |

3,30 ± 0,45 |

|

Ø 75 / 22 |

≥ 75,0 |

≤ 22,0 |

3,70 ± 0,5 |

|

Ø 85 / 25 |

≥ 85,0 |

≤ 25,0 |

3,70 ± 0,5 |

|

Ø 95 / 30 |

≥ 95,0 |

≤ 30,0 |

3,70 ± 0,5 |

|

Ø 115 / 34 |

≥ 115,0 |

≤ 34,0 |

3,70 ± 0,5 |

|

Ø 130 / 38 |

≥ 130,0 |

≤ 38,0 |

3,70 ± 0,5 |

|

Ø 140 / 42 |

≥ 140,0 |

≤ 42,0 |

3,70 ± 0,5 |

|

Ø 160 / 50 |

≥ 160,0 |

≤ 50,0 |

3,70 ± 0,5 |

|

Ø 175 / 58 |

≥ 175,0 |

≤ 58,0 |

3,70 ± 0,5 |

|

Ø 210 / 65 |

≥ 210,0 |

≤ 65,0 |

3,70 ± 0,5 |

|

Ø 220 / 75 |

≥ 220,0 |

≤ 75,0 |

3,70 ± 0,5 |

|

Ø 230 / 78 |

≥ 230,0 |

≤ 78,0 |

3,70 ± 0,5 |

|

Ø 240 / 80 |

≥ 240,0 |

≤ 80,0 |

3,70 ± 0,5 |

|

Ø 250 / 75 |

≥ 250,0 |

≤ 75,0 |

3,70 ± 0,5 |

|

Ø 260 / 80 |

≥ 260,0 |

≤ 80,0 |

3,80 ± 0,5 |

|

Ø 300 / 85 |

≥ 300,0 |

≤ 85,0 |

3,80 ± 0,5 |

|

Ø 350 / 95 |

≥ 350,0 |

≤ 95,0 |

3,80 ± 0,5 |